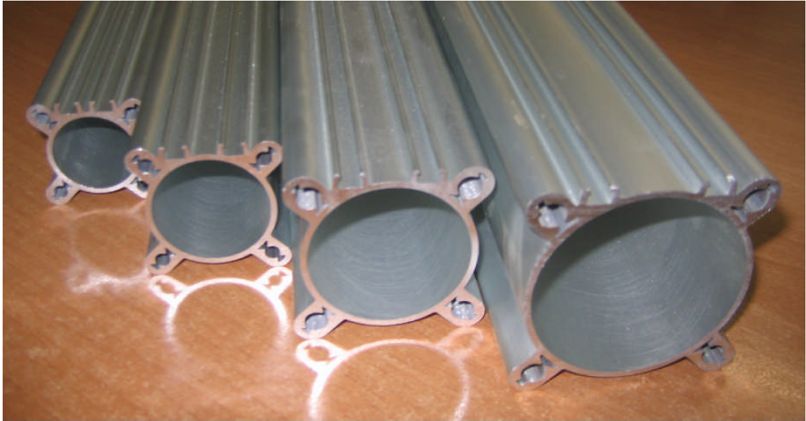

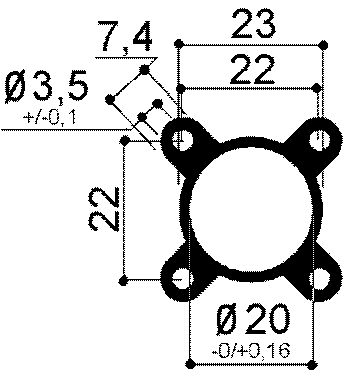

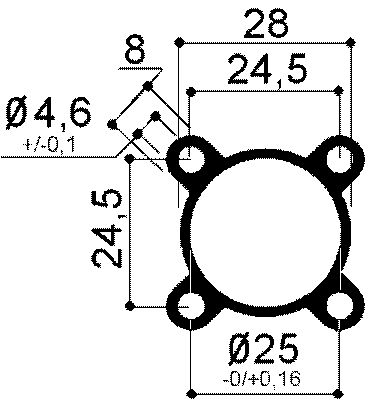

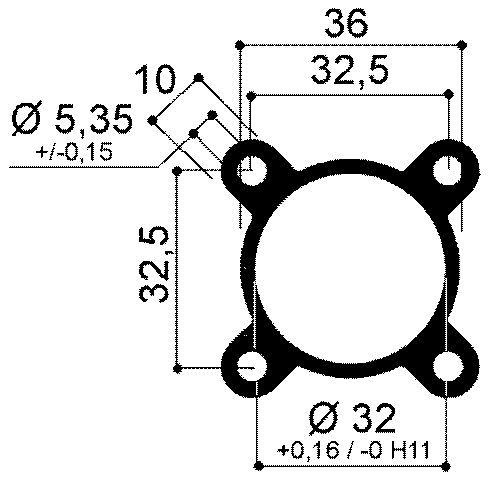

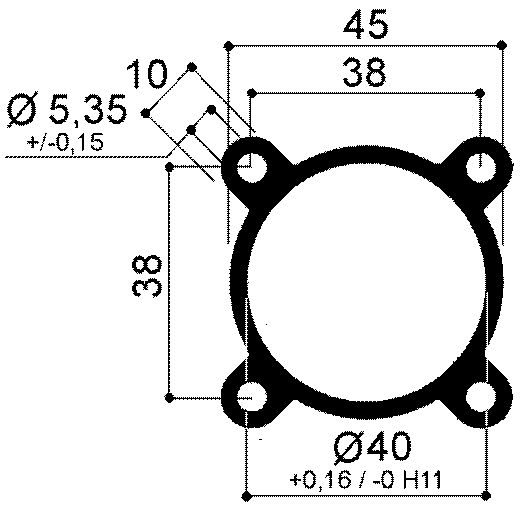

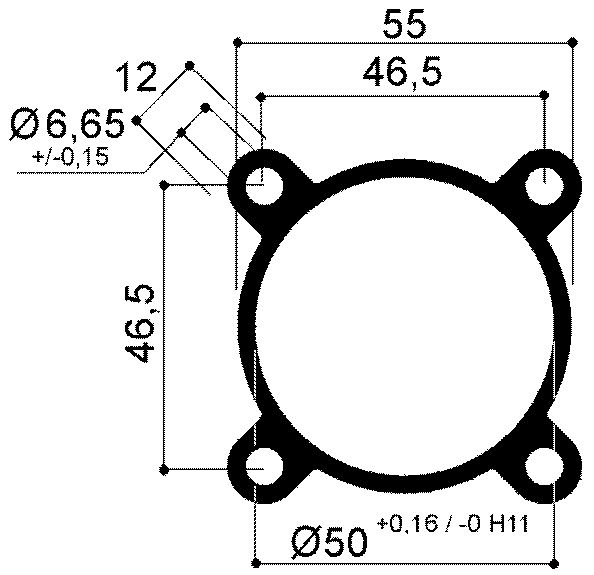

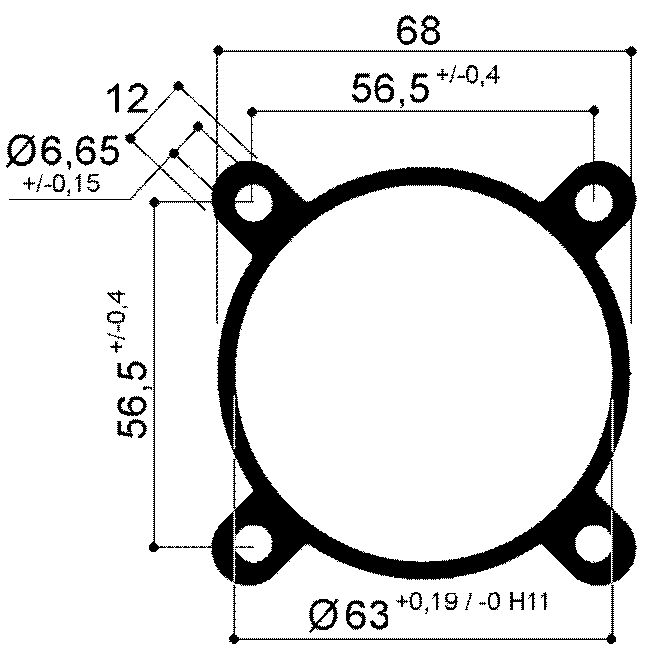

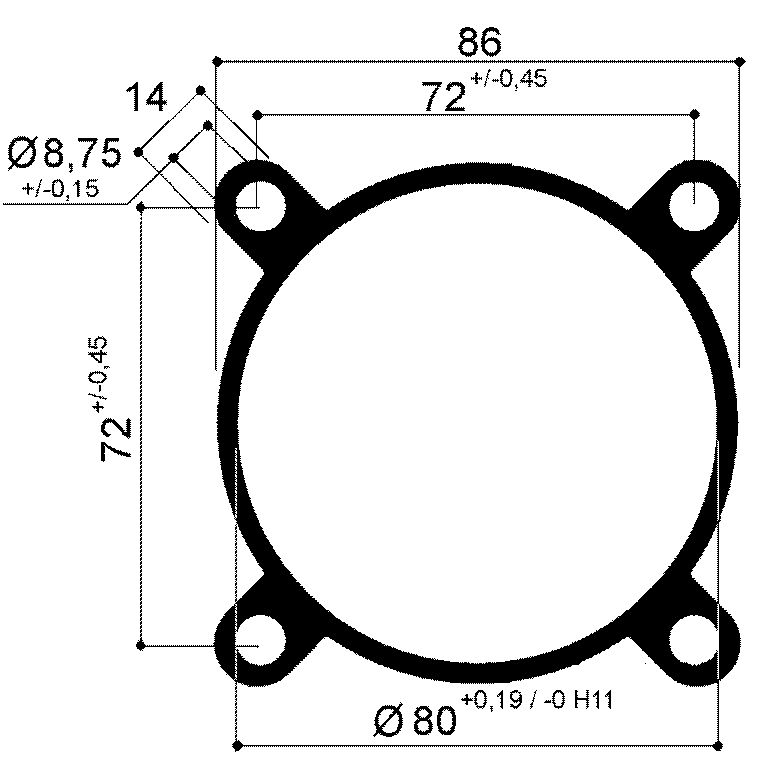

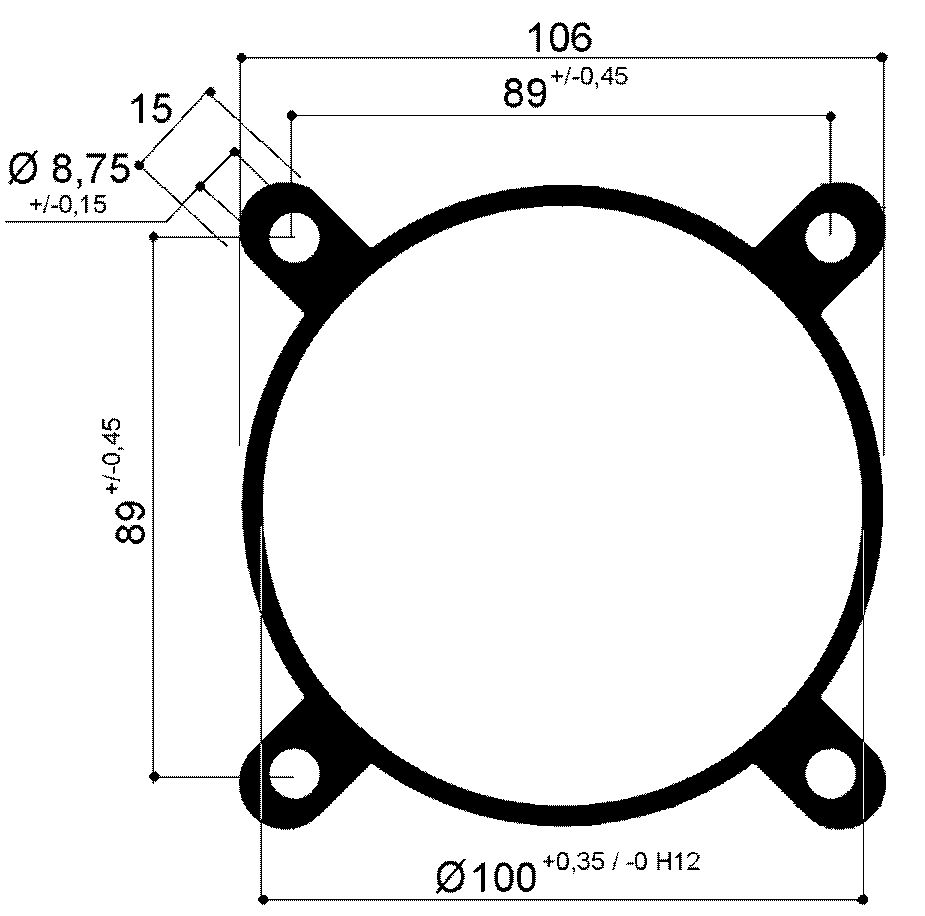

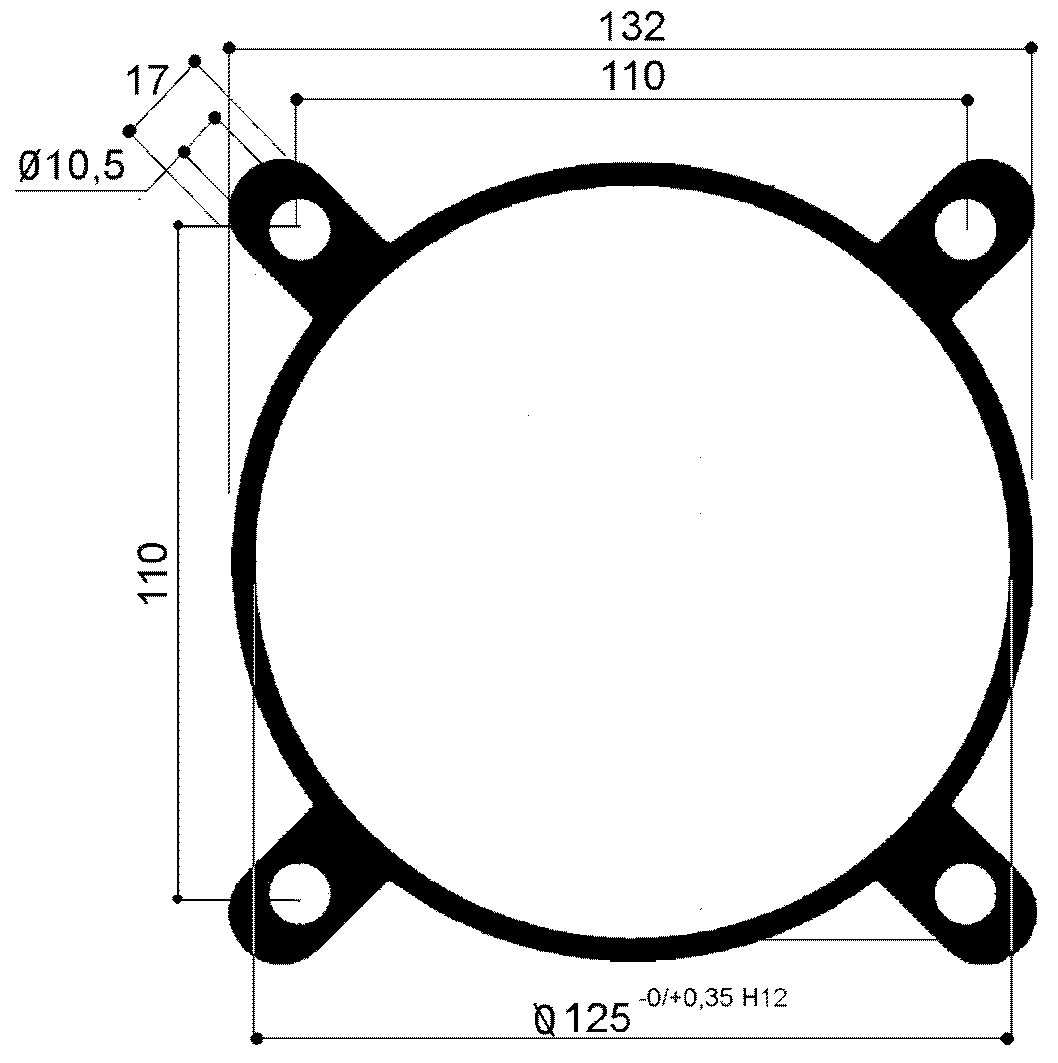

ALUMINUM TUBES FOR PNEUMATIC CYLINDERS: SERIES 80 Mickey Mouse type

Aluminum tubes suitable for the production of pneumatic cylinders for drives. These tubes are extruded, in aluminum alloy EN-AW6060T6 / EN-AW6063T6 subsequently calibrated - broached by mechanical processing and finally anodized class 20 µm

NOTE: TECHNICAL CHARACTERISTICS HIGH QUALITY PRODUCT after an accurate

extrusion the profile is subjected to a special cold calibration process of

the jacket (internal part). The peculiar characteristic of the 80 series

profiles is that the holes placed on the "ears" are threadable with metric

pitch traditional thread

Minimum mechanical characteristics:

Rm= Mpa 245 Rp0,2= Mpa 200 A5%=8 HBW=80

Anodizing:

- oxide layer thickness: class 20 µm +10/-4 (internal) +10/-8 (external)

- oxide layer hardness: 420 HV25 +130/-30

Roughness internal diameter:

Roughness' internal diameter: - Radial Ra ≤ 0.6 µm - Radial Rmax ≤ 9 µm - Axial Ra ≤ 0.4 µm

Full range of our aluminium profiles available on the website: www.omar-alluminio.it

The fixing holes are prepared for metric threading using traditional chip-removal tapping.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|